The relevance of solid substances nanoscale grinding technologies

Nowadays everybody knows what “nanotechnology” or “nano-sized particles” mean. Over the past twenty years nanotechnology has become a strategic industrial direction - more than 50 countries research and develop the field of nanotechnology, and at least 30 countries have their own national programs in this area.

Six Nobel prizes have been awarded for unique research results in the field of nanomaterials, nanotechnology, and nanoelectronics. According to estimates the development of nanotechnologies will change the twenty first century like atomic energy, the invention of the laser, the transistor, and the computer changed the twentieth century.

Today, nanotechnology is present in almost all areas of science and technology: physics, chemistry, materials science, biology, medicine, ecology, agriculture, and more. The scientific community estimates that the development of nanotechnology and nanosubstances will lead to the restructuring of all sectors of industrial production, lead to a new scientific technological revolution, and impact on the development of the social structure of society.

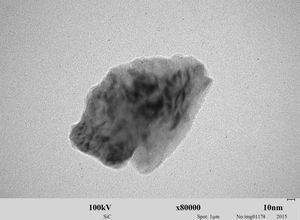

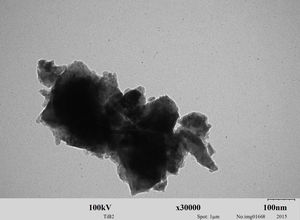

Nanotechnology is an interdisciplinary field of science and technology dedicated to the study of the properties of objects and developing devices with the basic structural elements of the dimensions of a few tens of nanometers (1 nm = 10-9 m). It is considered to assign everything less than 100 nm to the nanosystems industry. However, the system gets the prefix "nano,” not because its size becomes smaller than 100 nm, but due to the fact that its properties begin to depend on size. The macroscopic representation of the physical and physicochemical properties of the substance are invariant with respect to its quantity or size. However, this statement is true to a certain extent, that is, when at least one dimension in the length of the studied object becomes less than 100 nm. When nanoparticles form the system their properties differ either from the bulk phase of the substance or from the molecules and atoms they consist of. The basis of new achievements in nanoscale scientific and technological development is the usage of new previously unknown properties and functionality of material systems.

The first mention of the techniques, that later would be called nanotechnology, belongs to American physicist Richard Feynman in his famous lecture “here's Plenty of Room at the Bottom” in 1959. Feynman scientifically proved that there are no obstacles to produce physical objects directly from the atoms according to the fundamental laws of physics. He suggested that it is possible to move atoms separately, mechanically, using a manipulator of appropriate dimensions. For the first time the term "nanotechnology" was used by Japanese physicist Norio Taniguchi in 1974. He proposed to name production of nanometer-sized objects with this term. In 1986, the American futurist Eric Drexler published his book "Engines of Creation: coming Era of Nanotechnology” and the term nanotechnology has become known to the general public.

One should mention that there are at least two factors going along with research in the field of nanomaterials. Firstly, even at the beginning of study the possibility of realizing a high level of physical-chemical and mechanical properties of nanomaterials appeared. Secondly, these problems reveal a number of gaps not only in understanding the nature of the features of this state, but also its technological implementation.

In the transition from basic research to industrial processes that require not grams or kilograms, but tens and hundreds of tons of material with nanoscale particles, we often meet an insurmountable factor for their implementation which is high cost of nanomaterials. Therefore, the new technology of getting nanoparticles with low energy consumption and industrial scale will enable us to create a revolution in many fields of technology and production.